When selecting the perfect steel for a knife, two names that often come up are CPM 154 and S30V. Both steels are highly regarded in the knife-making community for their excellent performance, but they differ in several key areas.

This article provides a detailed comparison between CPM 154 and S30V, focusing on scientific data and measurable properties like chemical composition, edge retention, toughness, hardness, and corrosion resistance.

CPM 154 is a powder metallurgy version of 154CM, offering improved toughness and wear resistance. It is known for its fine carbide distribution, which results in better edge stability and easier sharpening. On the other hand, S30V was specifically developed for knives by Crucible Industries with input from renowned knife maker Chris Reeve. It is celebrated for its excellent edge retention and balanced toughness.

In this article, we will explore the differences between these two steels by analyzing their chemical composition, performance metrics (edge retention, toughness, hardness), heat treatment requirements, real-world performance characteristics, and manufacturing considerations.

Composition Analysis

The chemical composition of a steel determines its core properties such as hardness, toughness, corrosion resistance, and wear resistance. Below is a comparison of the chemical makeup of CPM 154 and S30V:

| Element | CPM 154 (%) | S30V (%) |

|---|---|---|

| Carbon (C) | 1.05 | 1.45 |

| Chromium (Cr) | 14.00 | 14.00 |

| Molybdenum (Mo) | 4.00 | 2.00 |

| Vanadium (V) | 0.40 | 4.00 |

Key Alloying Elements

- Carbon: Higher carbon content in S30V (1.45%) contributes to greater hardness and edge retention compared to CPM 154 (1.05%).

- Chromium: Both steels contain 14% chromium, making them stainless steels with good corrosion resistance.

- Vanadium: S30V has significantly more vanadium (4%) than CPM 154 (0.40%), which leads to the formation of hard vanadium carbides that improve wear resistance and edge retention.

- Molybdenum: CPM 154 has twice as much molybdenum as S30V (4% vs. 2%), which enhances toughness and corrosion resistance.

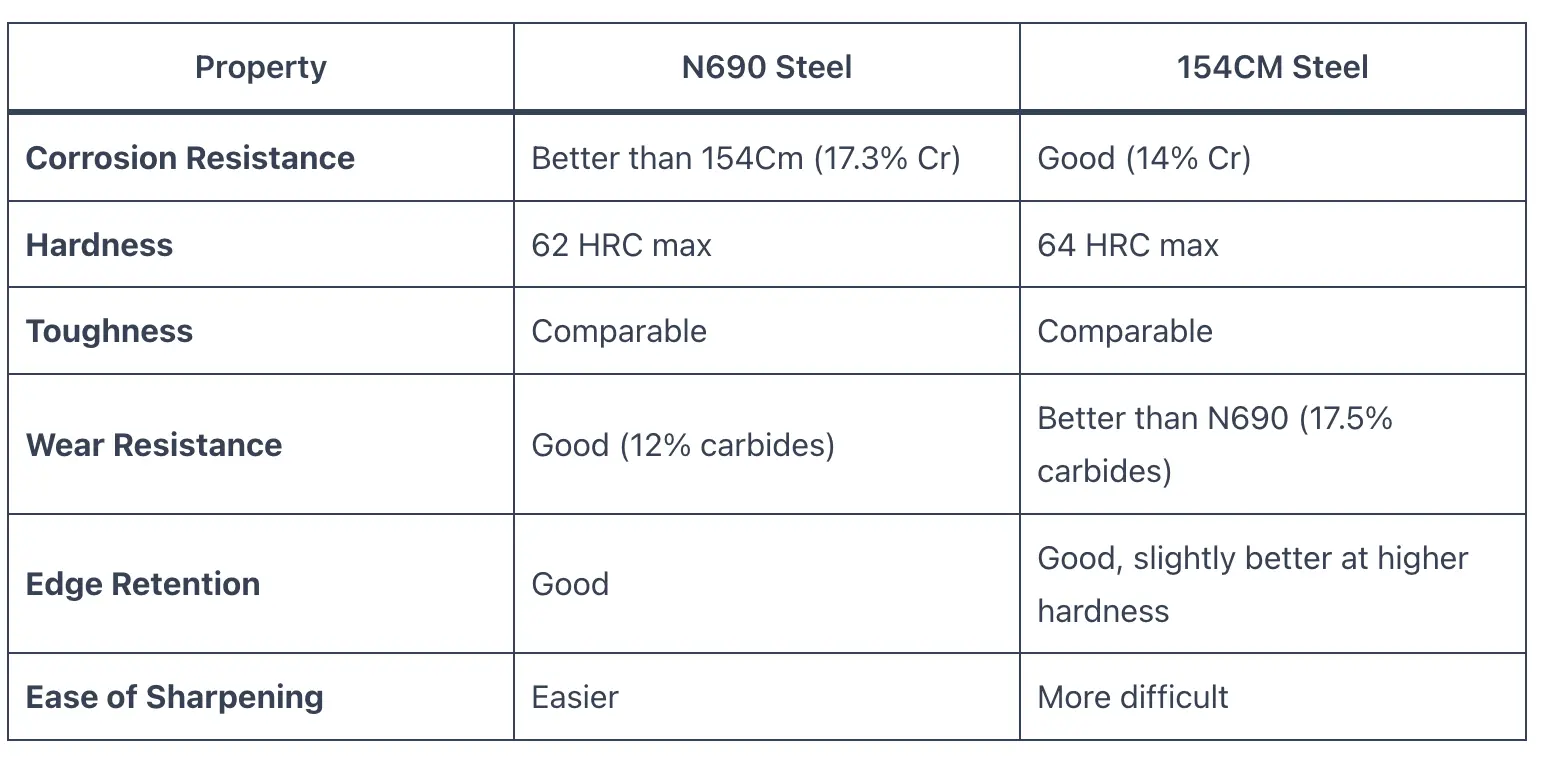

Direct Comparison Table

To provide a clearer picture of how these two steels compare across various properties, here is a side-by-side comparison:

| Property | CPM 154 | S30V |

|---|---|---|

| Edge Retention | Good | Excellent |

| Toughness | Better | Good |

| Corrosion Resistance | High | Very High |

| Maximum Hardness | Up to 61 HRC | Up to 64 HRC |

| Cost Factor | Moderate | Higher |

Performance Metrics

Edge Retention

Edge retention is one of the most important factors when choosing a knife steel. It refers to how long a blade can hold its sharpness during use.

- CPM 154: Known for good edge retention due to its fine carbide distribution. It performs well in everyday cutting tasks but falls short compared to higher vanadium steels.

- S30V: S30V excels in edge retention due to its high vanadium content (4%), which forms hard vanadium carbides that resist wear over time. In CATRA tests (which measure slicing edge retention), S30V outperforms CPM 154 by approximately 20%.

Toughness

Toughness refers to a material’s ability to resist chipping or breaking under stress.

- CPM 154: Offers better toughness than S30V due to its lower vanadium content and higher molybdenum content. This makes it less prone to chipping during heavy-duty tasks like chopping or batoning.

- S30V: While still tough enough for most applications, S30V is more prone to chipping under extreme conditions due to its higher hardness.

Corrosion Resistance

Both CPM 154 and S30V are stainless steels with excellent corrosion resistance due to their high chromium content.

- CPM 154: Offers high corrosion resistance thanks to its balanced composition of chromium and molybdenum.

- S30V: Slightly better corrosion resistance than CPM 154 due to the presence of vanadium carbides that prevent chromium from forming carbides, leaving more free chromium available for rust prevention.

Hardness Range

Hardness is measured on the Rockwell C scale (HRC) and indicates how resistant the steel is to deformation under load.

- CPM 154: Typically hardened between 58-61 HRC, making it easier to sharpen but still providing good wear resistance.

- S30V: Can reach up to 64 HRC, though it is usually tempered back to around 58-62 HRC for better toughness.

Heat Treatment Considerations

The heat treatment process significantly affects the performance characteristics of both steels.

CPM 154 Heat Treatment

For optimal performance:

- Preheat at 1400°F (760°C).

- Austenitize at 1950°F (1065°C) for maximum toughness or up to 2050°F (1120°C) for maximum edge retention.

- Quench using oil or air pressure quenching.

- Temper at around 950°F -1000°F, depending on desired hardness.

Cryogenic treatment can be applied after quenching for increased hardness and dimensional stability.

S30V Heat Treatment

For optimal performance:

- Preheat at 1550°F -1600°F (845°C -870°C).

- Austenitize at around 1950°F (1065°C).

- Quench using air or oil quenching.

- Double temper at around 600°F (315°C) for maximum stress relief and hardness stabilization.

Cryogenic treatment between tempers can further enhance hardness by minimizing retained austenite.

Real-World Performance Characteristics

Edge Stability

Edge stability refers to how well a blade maintains its sharpness without chipping or rolling under use.

- CPM 154: Offers good edge stability due to its fine carbide structure, making it less prone to micro-chipping even under heavy use.

- S30V: While offering excellent edge retention, it can be more prone to micro-chipping due to its higher hardness and larger carbide size.

Sharpening Behavior

Ease of sharpening is an important consideration for users who frequently maintain their blades.

- CPM 154: Easier to sharpen than S30V because of its lower hardness and finer carbide structure.

- S30V: More challenging to sharpen due to its higher hardness and larger vanadium carbides but holds an edge longer once sharpened.

Wear Patterns

Both steels exhibit different wear patterns based on their carbide composition:

- CPM 154: Wears more evenly due to smaller carbides, leading to smoother edges over time.

- S30V: Exhibits more aggressive wear patterns because of larger vanadium carbides that resist abrasion but may lead to uneven dulling over time.

Manufacturing Considerations

Both CPM 154 and S30V are produced using Crucible’s Powder Metallurgy process, which results in finer grain structures compared to conventionally produced steels. However, there are some differences in cost implications:

Cost Implications

- CPM 154: Generally more affordable than S30V because it contains less expensive alloying elements like vanadium.

- S30V: More expensive due to higher amounts of vanadium and the complexity of achieving optimal heat treatment results.

Conclusion & Use Case Recommendations

Both CPM 154 and S30V are excellent choices for knife steel but cater to slightly different needs:

- If you need a blade with superior toughness that can withstand heavy-duty tasks without chipping or breaking easily—especially in outdoor or survival situations—then CPM 154 is the better choice.

- If you prioritize long-lasting sharpness with minimal maintenance—ideal for everyday carry knives or culinary applications—then go with S30V, especially if you don’t mind the additional effort required during sharpening.

Ultimately, your choice should depend on your specific use case:

- For heavy-duty outdoor knives or tools where toughness is crucial: Choose CPM 154.

- For everyday carry or kitchen knives where edge retention is paramount: Choose S30V.

FAQs

- Which steel holds an edge longer?

- S30V holds an edge longer due to its higher vanadium content.

- Which steel is easier to sharpen?

- CPM 154 is easier to sharpen because it has lower hardness compared to S30V.

- Which steel is tougher?

- CPM 154 offers better toughness, making it less prone to chipping during heavy use.

- Which steel has better corrosion resistance?

- Both have excellent corrosion resistance, but S30V has a slight advantage due to its balanced carbide structure.

- Which steel is more affordable?

- Generally speaking, CPM 154 is more affordable than S30V due to lower alloying costs.

Citations:

[1] https://www.knifemaker.ca/products/cpm-154

[2] https://knifesteelnerds.com/2021/10/19/knife-steels-rated-by-a-metallurgist-toughness-edge-retention-and-corrosion-resistance/

[3] https://blog.hdmdknives.com/s30v-steel.html

[4] https://vegasforge.com/blogs/how-tos/how-to-heat-treat-carbon-3v-cpm-154-damascus

[5] https://knifesteelnerds.com/2020/03/16/how-to-heat-treat-cpm-154-toughness-experiments/

[6] https://www.crucible.com/pdfs/BladeShowBookletFinal05092016.pdf

[7] https://nobliecustomknives.com/cpm-s30v-steel/

[8] https://knifesteelnerds.com/2020/04/13/s30v-steel-history-and-properties/

[9] https://www.messerworld.de/en/ratgeber/cpm-154

[10] https://www.hudsontoolsteel.com/technical-data/steelCPMS30V

[11] https://damascussteelbillets.com/s30v-vs-cpm154/

Leave a Reply