When selecting steel for knives, two popular options frequently arise: CPM 3V and CPM S30V. Both are premium-grade steels manufactured using Crucible Particle Metallurgy (CPM), a process that enhances the performance of steel by creating a fine, uniform microstructure. However, despite sharing the same manufacturing process, these steels offer distinct properties that make them suitable for different applications.

- CPM 3V is renowned for its exceptional toughness and durability, making it ideal for heavy-duty tasks.

- CPM S30V, on the other hand, is favored for its excellent balance of edge retention, corrosion resistance, and ease of sharpening.

This article will dive deep into their chemical compositions, performance metrics, heat treatment requirements, and real-world applications. By the end, you’ll have a clear understanding of which steel suits your needs best.

Composition Analysis

The chemical composition of a steel significantly influences its properties such as hardness, toughness, wear resistance, and corrosion resistance. Below is a comparison of the key alloying elements in CPM 3V and CPM S30V.

| Element | CPM 3V | CPM S30V |

|---|---|---|

| Carbon (C) | 0.80% | 1.45% |

| Chromium (Cr) | 7.50% | 14.00% |

| Vanadium (V) | 2.75% | 4.00% |

| Molybdenum (Mo) | 1.30% | 2.00% |

Key Alloying Elements and Their Impact

- Carbon (C): Carbon increases hardness and edge retention. S30V has significantly more carbon than CPM 3V, which contributes to its superior edge retention.

- Chromium (Cr): Chromium enhances corrosion resistance. With 14% chromium content, S30V qualifies as stainless steel, whereas CPM 3V’s lower chromium content makes it more prone to rust.

- Vanadium (V): Vanadium improves wear resistance by forming hard vanadium carbides. Both steels contain vanadium, but S30V has more, contributing to its better wear resistance.

- Molybdenum (Mo): Molybdenum adds toughness and improves hardenability in both steels.

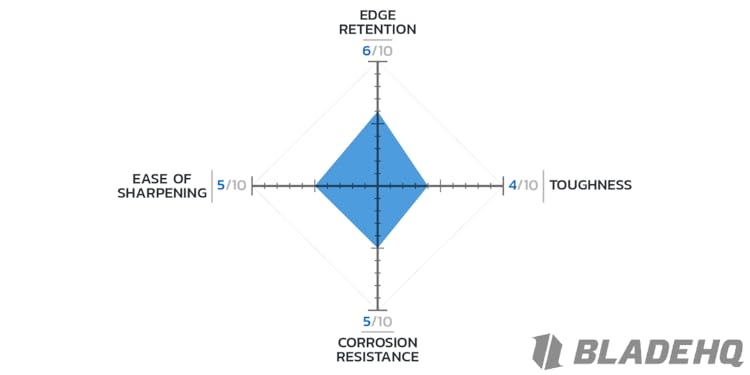

Direct Comparison of Properties

To better understand how these steels perform in practical applications, let’s compare their key properties:

| Property | CPM 3V | CPM S30V |

|---|---|---|

| Edge Retention | Moderate | High |

| Toughness | Exceptional | Good |

| Corrosion Resistance | Low | High |

| Maximum Hardness (HRC) | 58-60 | 58-61 |

| Cost Factor | Moderate | High |

Edge Retention

Edge retention is typically measured using the CATRA test, which evaluates how long a blade maintains its sharpness after repeated cutting tasks.

- CPM S30V: Scores higher in edge retention due to its higher carbon and vanadium content. It can maintain sharpness longer under normal use.

- CPM 3V: While not as strong in edge retention as S30V, it still performs well compared to other tool steels like D2 or A2[1][4].

Toughness

Toughness refers to a steel’s ability to resist chipping or breaking under impact or stress.

- CPM 3V: Known for exceptional toughness; it can withstand heavy use without chipping or breaking. This makes it ideal for survival knives or tools used in harsh environments[1][2].

- CPM S30V: While tough for a stainless steel, it cannot match the toughness of CPM 3V[5].

Corrosion Resistance

Corrosion resistance is crucial for knives exposed to moisture or harsh environments.

- CPM S30V: With 14% chromium content, it offers excellent corrosion resistance and is considered stainless steel[4][7].

- CPM 3V: With only 7.5% chromium, it is not stainless and will rust if not properly maintained[1][3].

Hardness

Hardness is measured on the Rockwell C scale (HRC), which indicates how well the steel can resist deformation under stress.

- CPM S30V: Can achieve a hardness range of 58-61 HRC after proper heat treatment[7].

- CPM 3V: Typically hardened to around 58-60 HRC but can be adjusted depending on the application[1].

Performance Metrics

Edge Retention (CATRA Test Results)

The CATRA test measures how long a blade retains its cutting edge after repeated slicing through abrasive material.

- S30V: Scores around 700 mm in CATRA tests due to its high vanadium carbide content.

- CPM 3V: Scores lower at around 500 mm, but still outperforms many other tool steels like A2 or D2[8].

Toughness (Charpy Impact Values)

Toughness is often measured using Charpy impact testing.

- CPM 3V: Has one of the highest Charpy impact values among knife steels at around 22 ft-lbs, making it extremely resistant to breakage[1][6].

- S30V: Offers moderate toughness with values around 7 ft-lbs, which is good for a stainless steel but far below CPM 3V[9].

Corrosion Resistance Ratings

Corrosion resistance is critical for knives used in humid or salty environments.

- S30V: Rated highly due to its high chromium content; it can withstand exposure to moisture without rusting easily.

- CPM 3V: Requires regular maintenance to avoid rusting; however, surface treatments like DLC coatings can improve corrosion resistance[1][5].

Heat Treatment Considerations

Both steels require precise heat treatment to optimize their properties.

CPM S30V Heat Treatment

Optimal heat treatment involves:

- Austenitizing at temperatures between 1900°F – 2000°F (1035°C -1095°C).

- Quenching in air or oil.

- Double tempering at temperatures between 400°F -750°F (200°C -400°C)[7].

The recommended hardness range after heat treatment is between 58 -61 HRC.

CPM 3V Heat Treatment

For optimal performance:

- Austenitize at around 1950°F (1065°C).

- Quench rapidly to avoid retained austenite.

- Triple temper at temperatures above 1000°F (540°C)[1][6].

The hardness after heat treatment typically falls between 58 -60 HRC, with higher hardness achievable at the cost of toughness.

Real World Performance Characteristics

Edge Stability

Edge stability refers to how well a blade maintains its sharp edge without deforming or chipping during use.

- CPM S30V: Offers excellent edge stability due to its high hardness and fine grain structure.

- CPM 3V: Provides superior edge stability under heavy use due to its exceptional toughness[1][4].

Sharpening Behavior

Sharpening behavior is influenced by the hardness and carbide content of the steel.

- S30V: Can be challenging to sharpen due to its high vanadium carbide content but holds an edge longer once sharpened[9].

- CPM 3V: Easier to sharpen than S30V because of its lower carbide volume but requires more frequent sharpening due to lower wear resistance[10].

Wear Patterns

Wear patterns refer to how evenly or unevenly a blade wears down over time with use.

- S30V: Wears slowly and evenly due to its high wear resistance.

- CPM 3V: Wears faster but more uniformly under heavy-duty tasks like chopping or batoning[9][10].

Practical Applications

CPM S30V

Best suited for:

- Everyday carry knives

- Kitchen knives

- Folding knives

Its superior corrosion resistance makes it ideal for environments where moisture exposure is common[4][9].

CPM 3V

Best suited for:

- Survival knives

- Outdoor tools

- Fixed-blade knives used in demanding conditions

Its high toughness makes it perfect for applications where impact resistance is critical[1][10].

Manufacturing Considerations

Both CPM S30V and CPM 3V are produced using Crucible Particle Metallurgy (CPM), which results in fine-grained microstructures that enhance their performance characteristics.

However:

- The production cost of CPM S30V is generally higher due to its more complex alloy composition and higher demand in premium knife markets.

In terms of ease of manufacturing:

- Both steels are difficult to machine due to their high hardness levels but benefit from improved grindability thanks to their fine microstructures[7][6].

Conclusion: Best Use Cases for Each Steel

In summary:

Choose CPM S30V if you need:

- Excellent edge retention

- Superior corrosion resistance

- A knife that requires less frequent sharpening

- Ideal for everyday carry or kitchen knives where moisture exposure is common.

Choose CPM 3V if you need:

- Exceptional toughness

- High impact resistance

- A blade that can withstand heavy-duty tasks like chopping or batoning

- Ideal for survival knives or outdoor tools used in rugged environments.

Both steels offer excellent performance when properly heat-treated and maintained, but your choice should depend on your specific needs—whether it’s toughness over sharpness or corrosion resistance over durability.

Citations:

[1] http://www.crucible.com/PDFs/DataSheets2010/ds3Vv1%202015.pdf

[2] https://www.diehlsteel.com/products/cpm-powder-metal/cpm-3v-powder-metal/

[3] https://www.knifeart.com/3v-steel.html

[4] https://blog.hdmdknives.com/s30v-steel.html

[5] https://nobliecustomknives.com/cpm-s30v-steel/

[6] https://www.mdpi.com/2073-4352/12/11/1670

[7] https://www.hudsontoolsteel.com/technical-data/steelCPMS30V

[8] https://knifesteelnerds.com/2021/10/19/knife-steels-rated-by-a-metallurgist-toughness-edge-retention-and-corrosion-resistance/

[9] https://en.wikipedia.org/wiki/CPM_S30V_steel

[10] https://polishcustomknives.com/blog/why-is-cpm-3v-powder-steel-so-strong

Leave a Reply